If you are in the Construction industry you have probably already heard the term CPM Scheduling. If you have not then you are about to enter an era of your career that will change everything in how you do business and complete projects. In this three-part guide we are going to jump into understanding CPM Scheduling, the history, how, when to use it and the benefits of implementing CPM Scheduling in Construction Projects.

In this first section we are going to dive into:

- The History of CPM Scheduling

- Key Concepts of CPM Scheduling

When we are finished with Part 1 of CPM Scheduling you will understand what it is, where it came from and the keys that will start the ignition to a technique that will put project success in overdrive. Let’s begin with:

What is CPM Scheduling?

CPM stands for Critical Path Method. The Critical Path Method scheduling is a technique used in project management. The CPM Scheduling technique is simply a scheduling process used to plan and control a sequence of tasks within a project. This technique is known as the critical path and using CPM scheduling will identify the longest path of dependent activities that will determine the project’s shortest duration to task completion. The critical path will take a major hit if anything on the path is delayed. These delays will interfere with the entire project’s completion date. So, if the Critical Path gets delayed then the whole project stands in delay. The CPM scheduling process will allow schedules to be built in scheduling tasks in an efficient manner, while managing all resources, and predicting the project completion date by honing in on the most time-sensitive activities to be done in the project.

Example of CPM Scheduling:

For a logical example let’s imagine our project is to build an office building. The lot that the office building is to be built on is on a forest-covered undeveloped track of land. Looking from the very beginning simply put there are some tasks that must happen in a specific order, while others that can be done at the same time. Let’s take a quick look in the over all large specific task to be completed:

- Clear the land – Before you can begin to build you will need a space to build it so trees and growth must be cleared and the ground must be leveled before anything else can occur.

- Lay foundation –Now that the land is cleared and the ground is leveled, we can now begin to lay the foundation.

- Construct build frame – The foundation must be completed before we can begin Constructing the building frame.

- Install plumbing and electrical –Now that the frame is up the plumbing and electrical installation can begin.

- Add walls and roof – Now that the frame is up the walls and roof can be added but the electrical and plumbing can overlap into this time period. The frame has to be completed to begin the electrical, plumbing, walls and the roof.

- Finishing Interior – Interior finishing is a task such as painting, flooring and installing fixtures. These tasks can only start when the walls and roof are built.

- Final inspections – This step can only be completed when ALL major work is completed. After all major work is completed then the building can be inspected for usage approval.

Now, you can see that the critical path is the sequence of tasks that must happen in a certain order in order for the project to reach an on-time completion date. If events occurred in the beginning when clearing the land and it was delayed, absolutely everything else does as well. The entire project gets pushed back. But some of the tasks, like the plumbing and electrical installation, can happen at the same time as other tasks are in operation, as long as they don’t interfere with the major critical steps.

CPM scheduling helps to identify these critical tasks so that delays do not occur or if they do, can be managed along with resources being gathered to be used efficiently in order to keep the project on track.

Now that you have a better understanding of what CPM Scheduling is, let’s take a look at where this technique came from.

The History of CPM Scheduling:

Origins of CPM Scheduling

In the late 1950s CPM Scheduling was developed. This became the response to inefficiencies, delays and all the wrong turns in project planning and scheduling. The combined efforts of two major organizations initiated the technique’s emergence. The joining organizations were the DuPont Corporation and Remington Rand UNIVAC.

The Collaboration began with DuPont and Remington Rand between 1956-1959 in Wilmington, Delaware by a Mathematician from Remington Rand UNIVAC by the name of James E. Kelley Jr. and Dupont Engineer Morgan R. Walker.

Facing increasing challenges in managing complex construction and maintenance projects was DuPont, a chemical manufacturing company. During this time, project planning’s reliance laid heavily on Gantt charts (bar charts). However, these charts were not able to include accountability for resource constraints and dependencies progressively.

This disability became problematic and needed solving. To achieve this solution, DuPont began collaboration with Remington Rand UNIVAC. Remington Rand, being an early computing pioneer, approached project scheduling development in a mathematical approach. Both parties shared goals were to create a more effective method that could systematically minimize project durations, identify task dependencies, optimize resource allocations and ultimately reduce the project overall cost.

1) CPM Development and Implementation

The Foundation of Mathematical Models

The identification of the most efficient sequences by mathematical models were heavily explored and tested by James Kelley and Morgan Walker. Their founded methods of identifying the best sequence of activities in a project was influenced by using graph theory, conducting operations research, and utilizing linear programming.

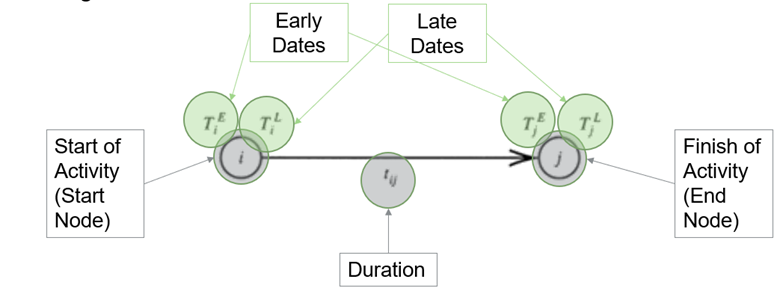

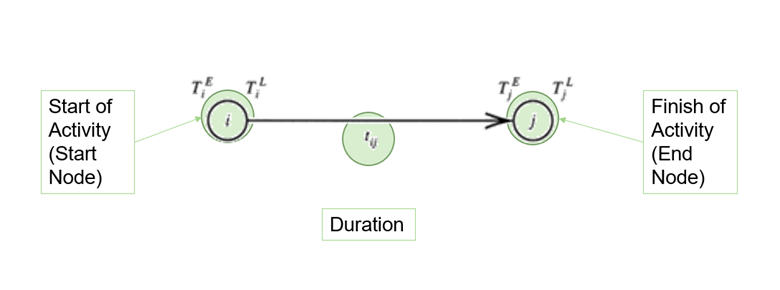

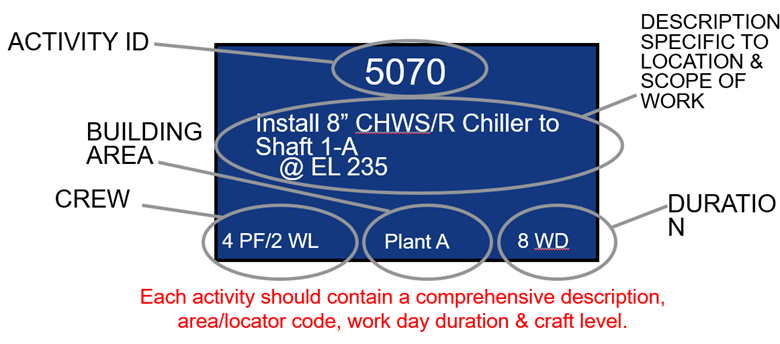

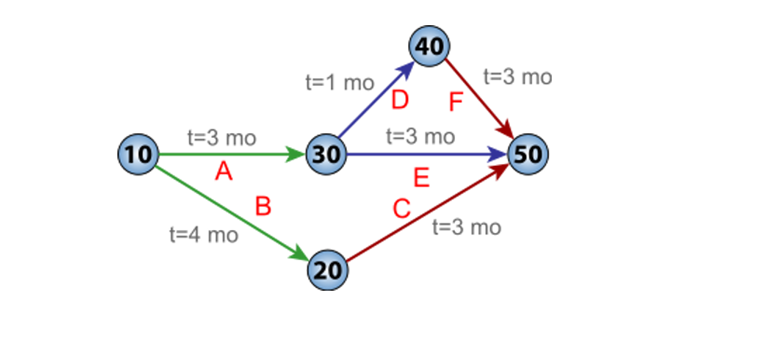

They developed a network-based model, implemented a universal key that used “Nodes” that represented project activities. These nodes were either circles or triangles. They used arrows or lines to represent dependencies between the project activities. Within this development the longest duration sequence of dependent activities would ultimately determine the project’s absolute shortest possible finish time. This became the project’s critical path.

Precedence Diagram Method (PDM)

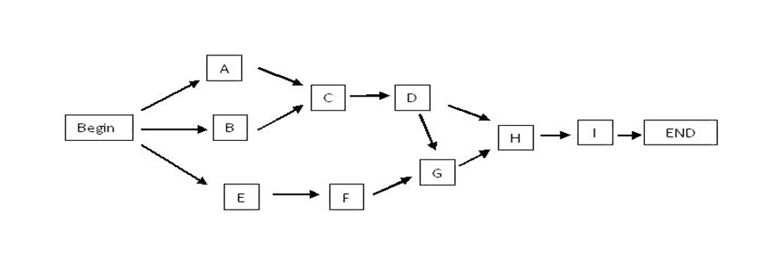

A critical path scheduling technique is PDM or Precedence Diagram Method used in construction project management. This method is a revolutionized network scheduling method that collaborates organization and visualization together while considering their logical relationships between activities.

PDM originated from the Critical Path Method (CPM), in the late 1950’s by DuPont and Remington Rand. This technique was intended to manage large-scale industrial and construction projects. CPM used an Activity-on-Arrow diagram. The AOA represented tasks as arrows and the dependencies as nodes. However, this method had limitations, especially as a representative in complex relationships along with different types of dependencies in between tasks.

In response to these limitations, the Precedence Diagram Method (PDM) was introduced by a professor at Stanford University in the 1960s, Dr. John Fondahl, John proposed PDM as a more effectively flexible alternative to AOA. This alternative allows activities to be represented as nodes (boxes) and the arrows connecting them represent the relationships. This shift greatly helped project scheduling capabilities by giving a more understandable representation of task dependencies.

Insertion and Adoption

The adoption of PDM increased rapidly due to its effective clarity it had to offer in handling larger and more complex projects. Whereas, AOA basically relied solely on Finish-to-Start (FS) relationships, PDM introduced four key dependency types that are now a standard fundamental in a more modern and present construction scheduling process. These key dependency types and examples are as follows:

- Finish-to-Start (FS) – Task B cannot start until Task A finishes.

- Start-to-Start (SS) – Task B cannot start until Task A starts.

- Finish-to-Finish (FF) – Task B cannot finish until Task A finishes.

- Start-to-Finish (SF) – Task B cannot finish until Task A starts (rarely used).

PDM’s all-around adaptability and exactitude made it an industry standard and became a formal procedure when the Project Management Institute (PMI) brought it into the Project Management Body of Knowledge (PMBOK) as an essential scheduling tool.

PDM predominately provides a clear visual, logical sequencing, and an effective process of resource allocation. These small benefits of using this technique make it invaluable for construction project scheduling. It allows project managers and planners to more sufficiently identify the critical path and meet deadlines. They can also optimize resource usage, preventing delays or overruns along with improving risk assessment by more easily anticipating potential bottlenecks.

Currently our modern project scheduling software such as Primavera P6 and Microsoft Project heavily rely on PDM, etching its status as a cornerstone of construction project management.

First Real-World Application (1958-1959)

After the development stage, the first Real-World application of CPM emerged in 1958 when the model was implemented by DuPont’s chemical plant maintenance shutdown project. This model astonishingly reduced the completion of the project from 125 days to just 93 days. This 32-day early completion saved a significant amount in cost. This occurrence also resulted in DuPont mandating CPM for its construction and maintenance projects.

By 1959, The formal introduction of CPM took place in their groundbreaking paper by both Kelley and Walker, at a meeting of the Operations Research Society of America.

Same Time Development: PERT (1957-1958)

Almost at the same time, a similar method called PERT or Program Evaluation and Review was in the works. This method was being developed for managing the Polaris submarine missile program by Booz Allen Hamilton and the U.S. Navy Special Projects Office.

The Key differences between the two methods are CPM is used for determining the time estimates and making projects timelier and more cost efficient for construction and industrial projects.

Whereas PERT is used for probability. These timing estimates make it more attainable for research and defense projects without certain timelines.</span>

The Great Evolution of CPM Scheduling From this point in time the CPM Scheduling method began to climb.

The Construction Industry, along with the Manufacturing Industries, began to adopt CPM. Major engineering firms and government agencies also began the adoption process. Projects that began to overtake the CPM method worked on projects such as highways, bridges, skyscrapers and larger more complex projects that were run by the U.S. Department of Defense. This integration also included other government programs such as NASA.

The 1970’s was the rise of mainframe computers with the capability of CPM calculation automation. Companies like IBM stepped into Computer Advancements and Software Development. They developed the early project scheduling software that reduced reliance on the current manual calculations. This was the dawn of automation in CPM scheduling.

Between the 1980s-1990s the Introduction of Personal Computers and Modern Software began to arise. In 1983 the user-friendly project management software like Primavera was founded and launched by 1984. IT sectors, aerospace, energy and construction industries started using CPM more widely.

By the 2000’s up to Present the Integration with modern CPM tools, AI, BIM, and Cloud Computing was largely active and using AI (artificial intelligence) for predictive analytics, and real-time team collaborations through cloud-based project management platforms while allowing remote project control.

Now that you have a solid understanding of the basics, continue exploring CPM scheduling in Part 2 of this series, where we explore advanced concepts and practical applications.

CPM Scheduling Today

Since the beginning of development to now CPM remains one of the most important scheduling techniques in project management. It has surely evolved with technology, and undoubtedly will continue. It has become an industry standard and is etched into the industry as part of the expected normal way of doing things. Companies of the industry that have since formed from development are companies that automatically are a part of PMBOK or Project Management Body of Knowledge. They also adhere to the CMAA (Construction Management Association of America and these guidelines have become requirements for many such as Government and defense contracting requirements.

Entering into this era in the present day from the mathematical model that began at DuPont and Remington Rand, CPM has certainly gained attraction in becoming a global standard in project management.