At its very essence, cost management is a strategic process, a guiding compass that engineers wield throughout the entire lifecycle of a project. It involves the delicate art of planning, cautious monitoring, and effective control of financial resources. Think of it as the trusted guide leading engineers through the intricate terrain of budgeting, meticulous expense tracking, and the orbit of financial decision-making. In this article, we will guide you regarding Cost Management Terms and how to handle them.

Why Cost Management Matters

In the rich needlepoint of engineering projects, effective cost management assumes the role of a linchpin, ensuring a delicate equilibrium between quality, time, and resources. It becomes the guardian of project viability, expertly aiding engineers as they navigate the fine line between delivering excellence and adhering to the constraints of budgetary reflections.

The Cost Management Lifecycle

The journey of cost management unfolds through distinct stages, each playing a critical role in sculpting the financial landscape of a project. From the initial phases of budgeting and cost estimation to the meticulous tracking of actual expenses and the ultimate analysis of variances, the cost management lifecycle is a comprehensive framework. It empowers engineers to keep financial equilibrium at every twist and turn of their project’s evolution.

Key Terms in Cost Management

To fluently converse in the language of cost management, engineers must acquaint themselves with fundamental terms such as budget, actual cost, earned value, and variance. These terms, akin to the vocabulary of financial control, enable engineers to articulate, analyze, and optimize the monetary aspects of their projects with finesse.

As we venture deeper into the Engineers’ Essential Guide to Cost Management Terms, our exploration will unravel the intricacies of budgeting techniques, delve into diverse methods of cost estimation, and harness the power of tools like Earned Value Management (EVM).

Cost Management terms

The methodology that leads to obtaining project performance

| Cashflow | The expected cost for the projects, as it is the variance between the cash-out and the cash-in |

| Budgeting | The baseline for measuring cost performance |

| Controlling | Controlling the project process to the project budget |

| Estimating | The approximation and breakdown of the resources allocated to the project or item. |

| Direct cost | The cost that can be exactly related to the item/service such as formwork to concrete works |

| Indirect cost | The cost that cannot be exactly allocated to the item/service such as technical and admin staff in the project |

| Overhead cost | Divided into:

Project overhead cost: which are the taxes and VAT that should be paid for the project. General overhead cost: it is the administrative percentage allocated to the project. |

| Profit | Equals to the total revenue – total expenses |

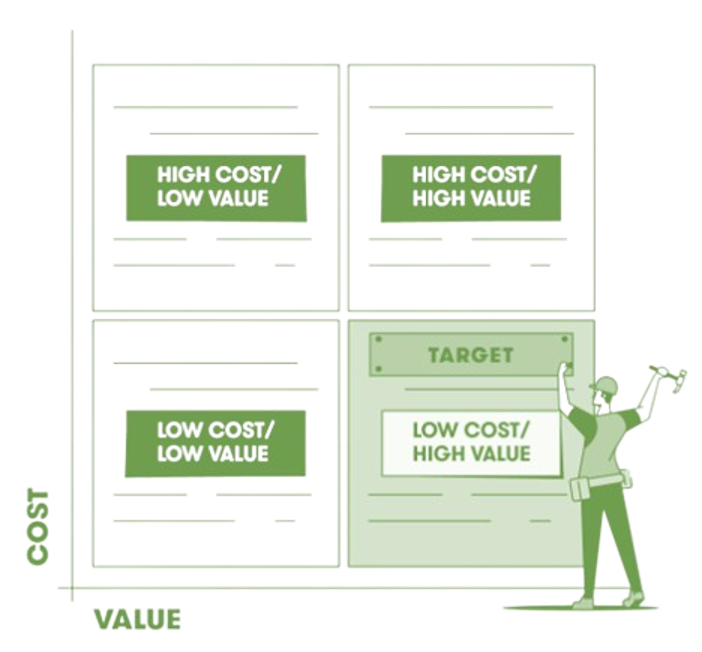

Value Engineering

Value engineering is the perspective for analyzing the project elements as the material, supplies, labor, and equipment which we can do to have the balance between cost and quality with greater value. It helps in reducing costs and having a higher profit with the perfect or best fit in outcomes. As it is the balance between project cost and quality to achieve the required function.

The most considered factors to perform a value engineering are:

- Cost

- Function

- Longevity

- Lead time.

The perfect time to perform value engineering is in the pre-construction phase to prevent any delay.

The most important steps in value engineering are:

- The 1st step in information gathering is to collect more data about the project.

- The 2nd step is to analyze the elements.

- The 3rd step is to have creative ideas.

- The 4th step is to develop these ideas and explore their impact on the project.

Advantages of value engineering

- Better decision making

- Create contingencies for the project.

- Building more relationships and building trust with the clients.

Common terms in project controlling

| AC | Actual Cost |

| ACWP | Actual Cost of Work Performed |

| ADM | Arrow Diagramming Method |

| AF | Actual Finish date |

| AOA | Activity-on-Arrow |

| AON | Activity-on-Node |

| AS | Actual Start date |

| BAC | Budget at Completion |

| BCWP | Budgeted Cost of Work Performed |

| BCWS | Budgeted Cost of Work Scheduled |

| BOM | Bill Of Materials |

| CAP | Control Account Plan |

| COQ | Cost of Quality |

| CPI | Cost Performance Index |

| CPM | Critical Path Method |

| CV | Cost Variance |

| CWBS | Contract Work Breakdown Structure |

| DD | Data Date |

| EAC | Estimate at Completion |

| EF | Early Finish date |

| ES | Early Start date |

| ETC | Estimate to Complete |

| EV | Earned Value |

| EVM | Earned Value Management |

| EVT | Earned Value Technique |

| FF | Finish-to-Finish |

| FF | Free Float |

| FMEA | Failure Mode and Effect Analysis |

| FS | Finish-to-Start |

| LF | Late Finish date |

| LS | Late Start date |

| OBS | Organizational Breakdown Structure |

| OD | Original Duration |

| PC | Percent Complete |

| PDM | Precedence Diagramming Method |

| PF | Planned Finish date |

| PM | Project Management or Project Manager |

| PMBOK® | Project Management Body of Knowledge |

| PMIS | Project Management Information System |

| PMO | Program Management Office or Project Management Office |

| PMP® | Project Management Professional |

| PS | Planned Start date |

| PSWBS | Project Summary Work Breakdown Structure |

| PV | Planned Value |

| QA | Quality Assurance |

| QC | Quality Control |

| RAM | Responsibility Assignment Matrix |

| RBS | Resource Breakdown Structure or Risk Breakdown Structure |

| RD | Remaining Duration |

| RFP | Request for Proposal |

| RFQ | Request for Quotation |

| SF | Scheduled Finish date |

| SF | Start-to-Finish |

| SOW | Statement of Work |

| SPI | Schedule Performance Index |

| SS | Scheduled Start date |

| SS | Start-to-Start |

| SV | Schedule Variance |

| SWOT | Strengths, Weaknesses, Opportunities, and Threats |

| TC | Target Completion date |

| TF | Target Finish date |

| TF | Total Float |

| T&M | Time and Material |

| TQM | Total Quality Management |

| TS | Target Start date |

| VE | Value Engineering |

| WBS | Work Breakdown Structure |

Understanding the CPM construction schedule is crucial for efficient project management. It helps streamline timelines and keeps your project on track, making cost management a breeze!