Revolutionize your construction project

What is a Digital Twin?

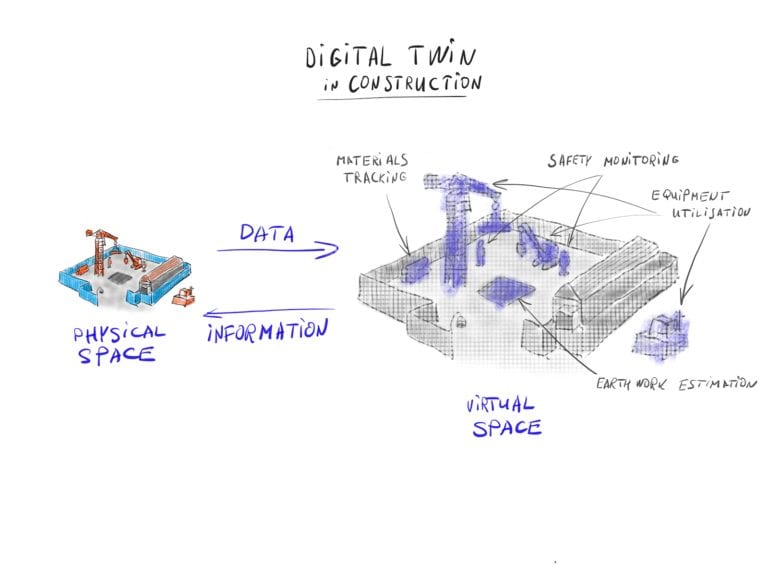

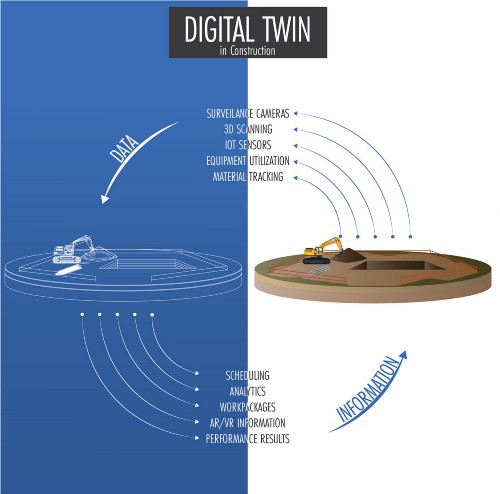

The Digital Twin of a building is a virtual model that collects real-world data with the aid of drones, sensors, robots, and other technologies. A digital twin is a link between the physical and the digital model that is continuously updated. The data collected in this virtual model is used to get valuable visualization about the project’s performance.

Digital Twin technology has been in use since 2002 in the fields of aerospace and astronautics. This concept is new in the construction industry, but it has enormous applications in this field, and it will change the perspective on the management of construction projects. Using digital twins in construction means that you have access to the as-built models in real time. It allows for comparing the progress with the 4D BIM model and timely decisions to keep the project on track.

Digital Twin technology has been in use since 2002 in the fields of aerospace and astronautics. This concept is new in the construction industry, but it has enormous applications in this field, and it will change the perspective on the management of construction projects. Using digital twins in construction means that you have access to the as-built models in real time. It allows for comparing the progress with the 4D BIM model and timely decisions to keep the project on track.

The key benefits of using Digital Twins in construction projects have been discussed here:

1. Cost Saving by Avoiding Reworks

BIM has been established as an international standard for optimizing and integrating the projects’ dimensions, construction details, and scheduling. But the question is, how would you compare the BIM models with the actual construction on-site? Access to the BIM model is only one part of the Digital Twin, but the data collected from the site with sensors’ help will update the as-built models on an ongoing basis. If there is any difference between the as-built and the as-planned models, it is indicated timely before the concrete pour is initiated. Thus, the primary advantage of digital twin technology is saving costly mistakes.

2. Improving the Collaboration

Digital twin technology is the two-way flow of information from the field to the digital twin and vice versa, and it becomes a powerful method of collaboration for all the parties involved in the project. All the teams are kept on the same page and unnecessary field visits can be avoided as the real-time data is available to make decisions. The top management can also make timely decisions as they have all the real data, and the probability of the project’s success is enhanced considerably.

3. Safety Monitoring

The construction industry is one of the most dangerous globally; it is a need for time to improve the safety of the workers at the site. This technology enables the real-time tracking of the workers in hazardous zones to prevent the use of unsafe methods or materials by the workers. It is also possible to use sensors in a critical area like scaffolding subjected to high loads to monitor the stresses during construction works to avoid the failure of the scaffolding platforms.

4. Handing Over, Operations and Maintenance

The project handing over is one of the biggest challenges for any construction project. The digital twin solves this issue as the digital model validates all the as-built deliverables. This data is highly reliable for the operations and maintenance of the facility. It becomes a source of transparency for the owner and one can rely on the data to verify the quality of the work being performed as per the design.

5. Health Monitoring of the Structures

The role of the digital twin does not end after the handing over of the project but this model can be used throughout the life cycle of the project. Consider a cement plant that consists of high structures like cement silos, raw mills, etc. It is necessary to keep an eye on the structural health as the vibrational and cyclic loads cause stresses that may cause the failure of the structure. These issues have been experienced in the past like the failure of cement silos in a running plant. Such incidents can be life-threatening and also cause serious financial losses. If the sensors are installed to monitor the cracks and stresses in a live structure and transmit this data to the digital model, it is possible to foresee this hazard of structural failure and take remedial measures timely.

Conclusion

The digital twin concept can be a key player in elevating the construction business. It has vast applications in construction projects of all types. The profit margins and safety levels can be increased in construction by implementing this technology.

Contact Leopard Project Controls for your next scheduling project.